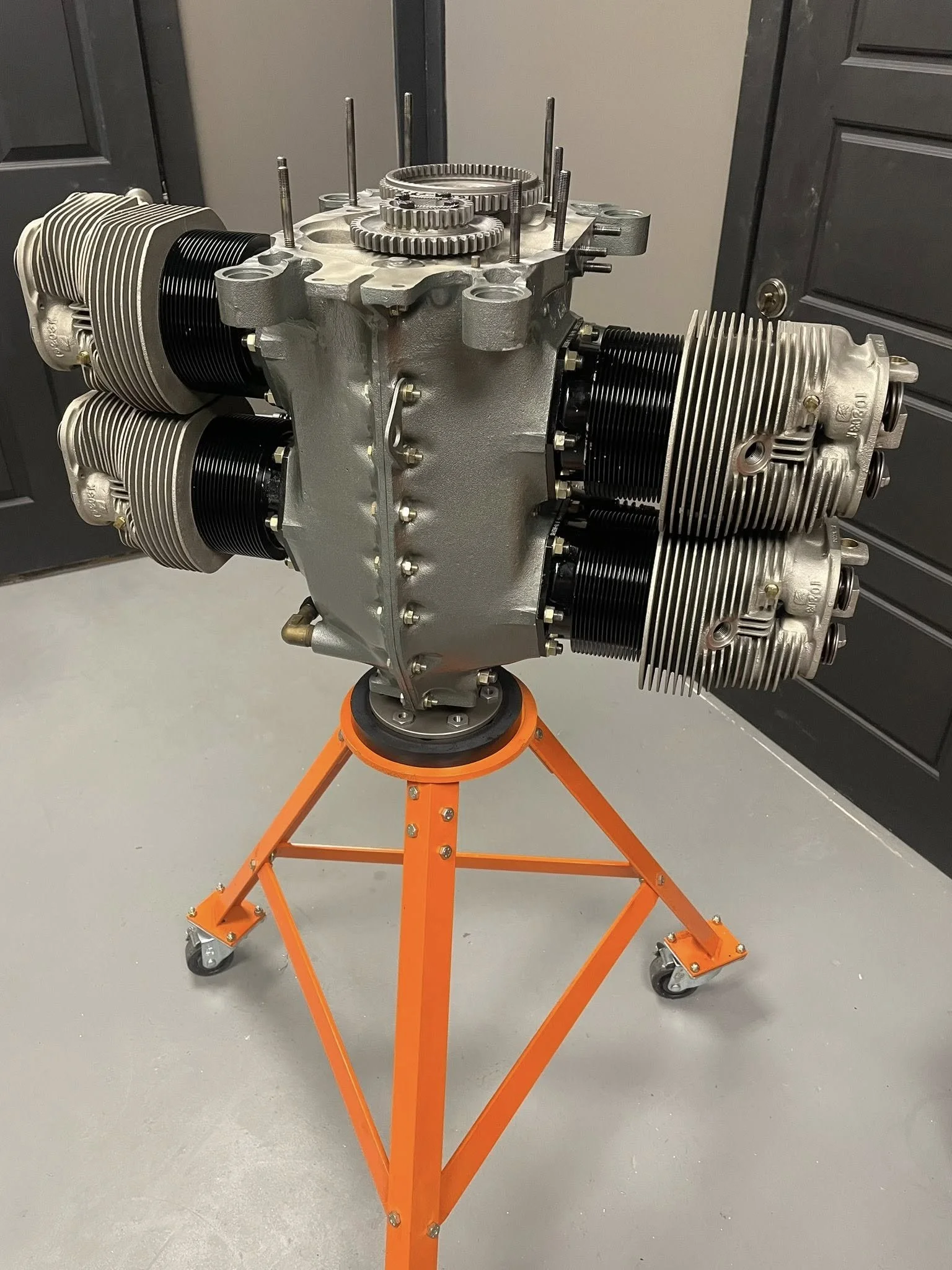

Custom Engine Build

Handcrafted performance with custom options from start to finish

Every aircraft and pilot has unique needs, your engine should too. At Labyrinth Aero Engines, we specialize in building fully customized aircraft engines designed around how you fly.

Whether you’re looking for enhanced performance, a signature finish, or a specific configuration, we’ll build an engine that’s as individual as your aircraft.

-

Tailored Engine Configuration — Built to your aircraft’s specifications and flight goals

Component Selection — Choose from factory-new or certified parts, new camshafts

Custom Finishes — Powder coating and paint options in a variety of colors to match your aircraft’s look

Precision Assembly — Each build is assigned a dedicated mechanic and inspector to ensure accuracy and compliance

Testing & Verification — Every custom engine undergoes full test-stand evaluation to confirm performance and reliability before delivery

-

Custom builds typically take 6–12 weeks, depending on component selection and finish options. Each project begins with a consultation to define your build goals, followed by a detailed proposal outlining configuration, parts, and estimated completion.

During the build, our team provides updates and progress photos so you can see your engine come together. Once testing is complete, we’ll crate and deliver it directly to your hangar — free delivery to airports in the Dallas/Fort Worth area.

-

Achieve optimal performance for your aircraft’s mission profile

Add personal touches with custom colors and finishes

Ensure every component is certified and precisely matched

Build with confidence — all engines meet factory-new tolerances and comply with applicable FAA, Lycoming, and Continental standards

Frequently Asked Questions

FAQ’s

-

A custom build is a complete engine assembled to your exact specifications — from internal components to external finishes. It allows you to optimize performance, appearance, and reliability based on your aircraft’s mission and your personal preferences.

-

Most custom builds take 6–12 weeks, depending on parts availability and the level of customization. Builds with factory-new or specialty components may take longer due to supplier lead times.

-

Yes. You can select from factory-new or certified components, including camshafts, cylinders, and tappet bodies. Our team will help guide part selection to ensure compatibility and performance.

-

Absolutely. We offer a variety of custom paint and powder-coating options, from classic alodine finishes to unique colors that match your aircraft.

-

Every engine is mounted on our test stand for performance verification. We measure oil pressure, oil temperature, CHT, EGT, manifold pressure, and RPM to ensure your engine runs perfectly before crating and delivery.

-

Yes. All engines are built to factory-new tolerances and backed by our shop warranty, which covers workmanship and components as detailed in your build agreement.

-

Yes. We provide progress updates and photos throughout the process, and you’re welcome to schedule a visit to our Dallas facility to see your build in person.

-

Yes. We provide free delivery to airports in the Dallas/Fort Worth area and can arrange secure nationwide shipping for all completed engines.